Customer Testimonials

– stories from our customers

”At Höganäs, we are continuously striving to reduce our energy consumption and climate footprint. Our investment in the Enairon Gravity Compressor marks a significant step forward in meeting our needs for compressed air. With high energy efficiency, it will not only lower costs but also enhance sustainability. Additionally, its quiet operation will improve our workspace. We look forward to installing the Gravity Compressor on our site.”

Magnus Pettersson, PhD

Energy Coordinator at Höganäs AB

Höganäs AB

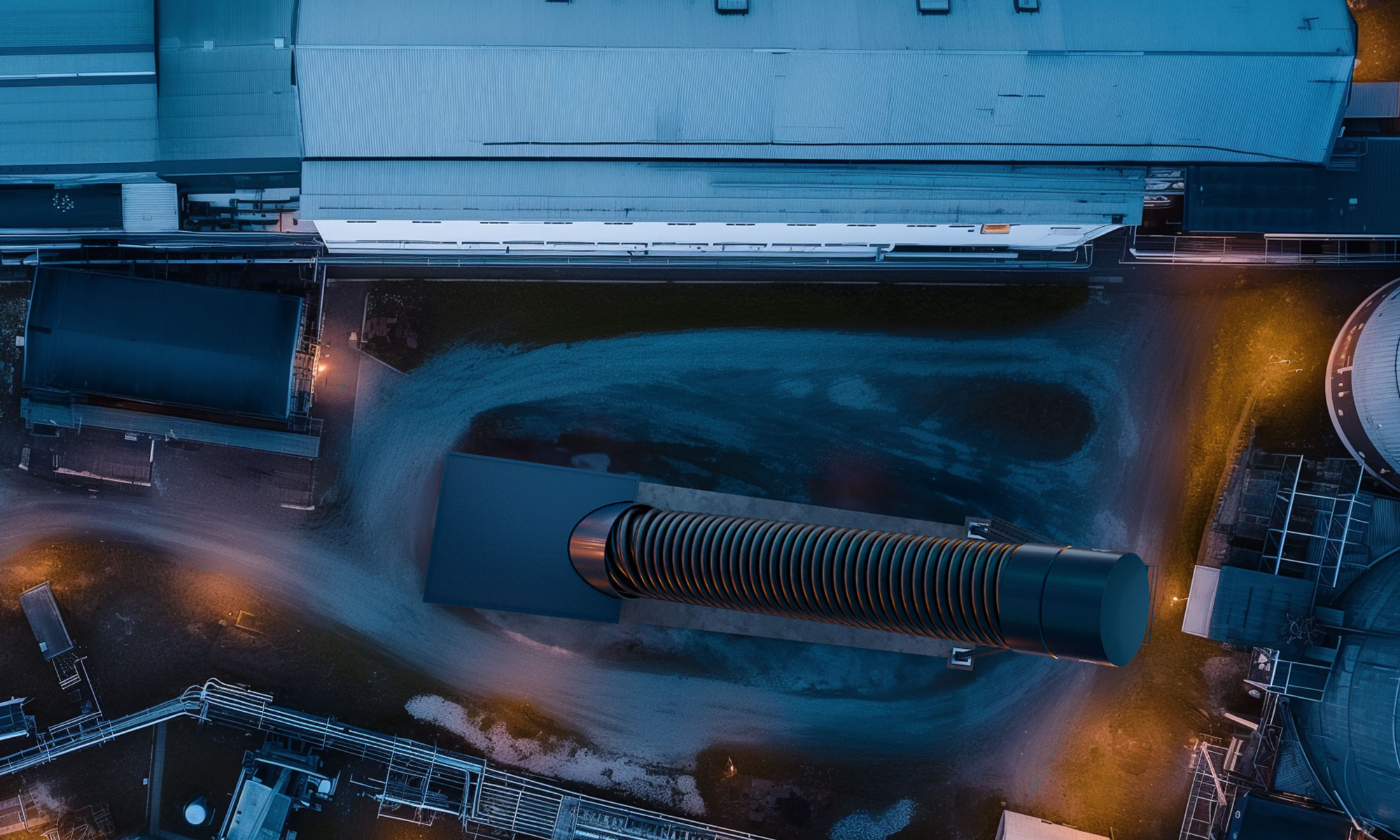

Höganäs AB, a leader in powder metallurgy, blends a rich legacy with cutting-edge innovation. Renowned globally, the company’s commitment to sustainable practices and precision solutions sets it apart. From automotive to industrial applications, Höganäs AB’s products redefine standards. With a global reach, efficient supply chains, and a focus on corporate responsibility, the company shapes a future where metal industries thrive sustainably.

Project

The project will introduce the next generation Gravity Compressor to Höganäs AB by 2025. The installation will take place at Höganäs headquarters in Sweden. The Enairon compressor’s capacity 5100 Ncbm is designed to efficiently manage peak airflow demands while also adapting to low-flow periods, optimizing energy consumption. The anticipated outcome includes a substantial 37% reduction in energy usage compared to Höganäs’ current air compressor solution. This compressor marks the inaugural release of Enairon’s next-generation Gravity Compressor, with plans for future mass production in the years to come.

Image ownership: Höganäs AB

”The world’s most efficient compressor was successfully installed at Stora Enso AB in a jointly financed project between Stora Enso and Enairon. The purpose of the project was to save electrical energy and pave the way for a technology that could revolutionize the compressor industry.”

Mats Marcus, Area Manager Energy Efficiency

Stora Enso AB

Stora Enso AB

Stora Enso AB, a leader in the industry, champions sustainability and quality. Part of the global Stora Enso Group, the company emphasizes responsible practices, delivering high-quality paper solutions globally. With a focus on innovation and eco-friendly manufacturing, Stora Enso AB shapes a sustainable future for the paper industry.

Project

The project agreement between Stora Enso AB and Enairon was established in 2019 with the objective of implementing the first large-scale verification of the Enairon Gravity Compressor. Following the successful construction of prototypes, the technology underwent extensive testing, providing a continuous and substantial air supply to the paper mill in Hylte Bruk over several months. The project achieved its goals, demonstrating the Enairon compressor’s success in managing fluctuating air demand within the factory. Operating at 7 bar, the 36kW compressor showcased remarkable flexibility, swiftly adjusting from 0 to 100% capacity in less than 10 seconds.

Daniel Ralphén, Technical Project Manager at Södra Cell

Södra Cell

Södra Cell initiated a study to evaluate the entire compressed air system approximately two years ago. The goal was to enhance overall efficiency and explore energy-efficient solutions available on the market. During the study, discussions with Enairon began. We visited Stora

Enso in Hyltebruk, where we observed the core technology operating in an industrial environment. After comparing various compressed air solutions, it became evident that investing in the Enairon Gravity Compressor was the most economically beneficial choice.

How did you evaluate the efficiency of your current compressed air solution?

We have power meters and flow meters installed after each compressor, allowing us to calculate the isothermal energy efficiency of each unit. On average, the efficiency across all three compressors was measured at 46.8%. We currently are using oilfree screw compressors from Atlas Copco.

Was the decision to invest in the Gravity Compressor purely economic?

While the decision was primarily economically driven, we see several additional benefits with the Gravity Compressor. One key advantage is the delivery of clean, 100% oil-free air. Although we currently use oil-free screw compressors, there is still a risk of oil contamination. With the Gravity Compressor, this risk is completely eliminated. Another important factor is noise reduction. Our internal regulations state that machines exceeding 80 dB should not be placed in environments where people work for extended periods. Additionally, we are committed to minimizing noise impact on our neighbours, and the Gravity Compressor will help reduce our overall noise profile. The cooler air output from the Gravity Compressor is another significant benefit. Lower air temperatures reduce the energy consumption of our dryers. For example, I recently learned that reducing the inlet air temperature from 40°C to 30°C for an airflow of 5,000 m³/h can lower power consumption from 60 kW to 28 kW. This represents substantial energy savings, further improving the overall energy efficiency and payback time of our investment. At Södra, we are focused on reducing overall energy consumption, and investing in energy-efficient machines aligns with this goal.

While economic factors are central to our decision-making, energy efficiency is an independent but complementary objective. Finally, the Gravity Compressor requires less maintenance and has a long projected lifespan, primarily due to its low rotational speed. Additionally, since the machine can be placed outdoors, we can free up valuable indoor space.

Describe the cooling water solution you plan to use for the Gravity

Compressor and how it will integrate with your heat recovery system.

Södra Cell has several cooling water systems, and for the Gravity Compressor, we will use chemically purified water from one of our existing cooling water networks. Our facility operates multiple cooling water systems, and we actively reuse the heat generated by our machines in various processes.

For the Gravity Compressor, we plan to repurpose the heated cooling water after it has absorbed energy from the compression process. One of the key advantages we recently realized is that 90% of the supplied energy is transferred to the cooling water, compared to only 50% in our current system. This allows us to utilize the recovered energy more efficiently in downstream processes, ultimately contributing to hot water generation.

Additionally, some processes at our site require cooling water that is not too cold. Here, we see an ideal opportunity to integrate the Gravity Compressor’s cooling water, reusing it in applications where slightly warmer cooling water is beneficial. This further optimizes our overall energy use and enhances system efficiency.

Our partners

– A part of Enairon

Our partner network thrives on a dynamic blend of individuals and organizations who share our belief in the potential of Enairon’s technology. We have carefully selected our partners based on their expertise, experience, and alignment with our long-term aspirations. With their help, we not only secure the necessary financial resources but also gain access to invaluable industry insights, guidance, and networks.

GU Ventures AB is an owner of Enairon AB and supports Enairon’s growth by accelerating the business development in their accelerator program. Business coach and board member Elisabeth Gustafsson, acts as a close advisor to the Enairon team.

The technological development at Enairon takes place in collaboration with researchers at Chalmers University of Technology. Magnus Karlsteen, Associate Professor in Physics, is one of the researchers driving the research and testing the performance of the technology.

Chalmers Ventures AB is an owner of Enairon AB and supports Enairon’s growth by accelerating the business development in their accelerator program. Business coach Håkan Axelsson, acts as a close advisor to the Enairon team.

”The technical solution has potential to be significantly more efficient and cheaper than today’s comparable solutions”.

– Håkan Axelsson, business coach at Chalmers Ventures Accelerator

Financial partners/ Contributors

In addition to our valued partner network, we are privileged to have received support from financiers who promote sustainable technology and development.

Want to know more?

Whether you have an inquiry, suggestion or just want to say hello, don’t hesitate to get in touch. We are here to provide additional information and answer any questions you may have. Simply click the button below and enter your inquiry and we will get back to you as soon as possible.