ENAIRON GRAVITY COMPRESSOR 400 MVSD-7

The world’s most

efficient compressor

Enairon’s compressor is a new type of compressor, a Gravity Compressor. It is different and stands out from all existing solutions and uses water to compress the air. The design mainly consists of pipes twisted in a spiral pattern where water acts as pistons to compress the air. Utilizing water and gravity the world’s most efficient process for compressing air is achieved.

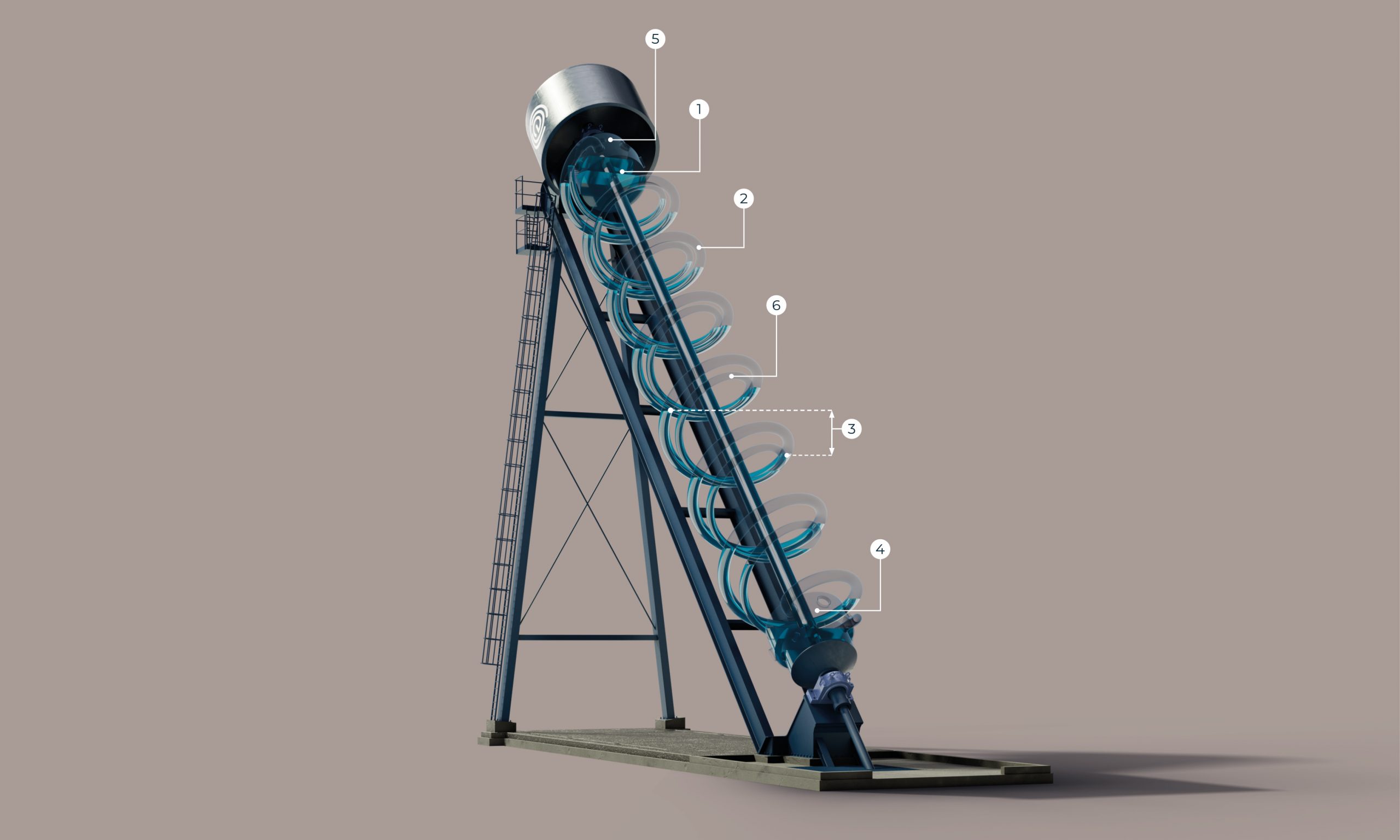

– Gravity Compressor Design

The compressor is constructed using PE-pipes with a continuously decreasing internal diameter, arranged in multiple spirals set at a 45-degree angle and organized in parallel. Each endpoint of every spiral is connected to two straight pipes running inside the spirals One manages the return of water within the spiral, connecting the endpoint with the starting point of the same spiral. The other straight pipe connects the endpoint of the current spiral to the starting point of the subsequent one, exclusively facilitating the passage of air. Throughout operation, water remains within its designated spiral, while air seamlessly moves from one spiral to the next as pressure accumulates and increases in stages, ultimately reaching the endpoint of the last spiral where the air has reached the end pressure. This thoughtfully engineered system, complemented by gravity, manages the separation of air and water, guaranteeing a seamless flow and process. Notably, the entire rotating apparatus operates passively, with only one single moving part. Once filled with water, the compressor necessitates no additional water intake; it solely requires air as the inflow and outputs only air.

How it works

– We use water & gravity to compress air

The process begins in a top tank (1) that draws in outside air.

The tank is half-filled with water, and air and water are alternately fed into spirals running down the compressor.

As the spirals rotate, gravity pushes the water and air downwards. The spiral volume per revolution decreases along the spiral (2).

Gravity strives to keep the water in a horizontal position, but air pressure pushes the water out of equilibrium, creating standing water pistons with height differences (3).

For each spiral revolution, these height differences create a higher pressure.

The compression process is efficiently cooled throughout the entire process due to the water, reaching an almost isothermal process with superior efficiency.

The spirals end in a bottom tank (4) where the water and compressed air are separated.

The water is recirculated to the top tank (1), utilizing its pressure and converting this pressure into potential energy that is reused in the spiral. The air moves on to the next stage’s top tank (5) and a new set of spirals (6) for further compression.

This process is repeated until the total pressure is reached. The air is delivered to consumers, such as a factory or an industry.

Product Advantages

– Enairon’s Gravity Compressor

The advantages of Enairon’s Gravity Compressor are listed and explained in relation to most common existing comparable solutions. We begin with the fundamental advantages of the technology, which give rise to its operational advantages.

Fundamental Advantages

Operational Advantages

“At Höganäs, we are continuously striving to reduce our energy consumption and climate footprint. Our investment in the Enairon Gravity Compressor marks a significant step forward in meeting our needs for compressed air. With high energy efficiency, it will not only lower costs but also enhance sustainability. Additionally, its quiet operation will improve our workspace. We look forward to installing the Gravity Compressor on our site.”

Magnus Pettersson, PhD

Energy Coordinator at Höganäs AB

Savings Calculator

– Enairon’s Gravity Compressor

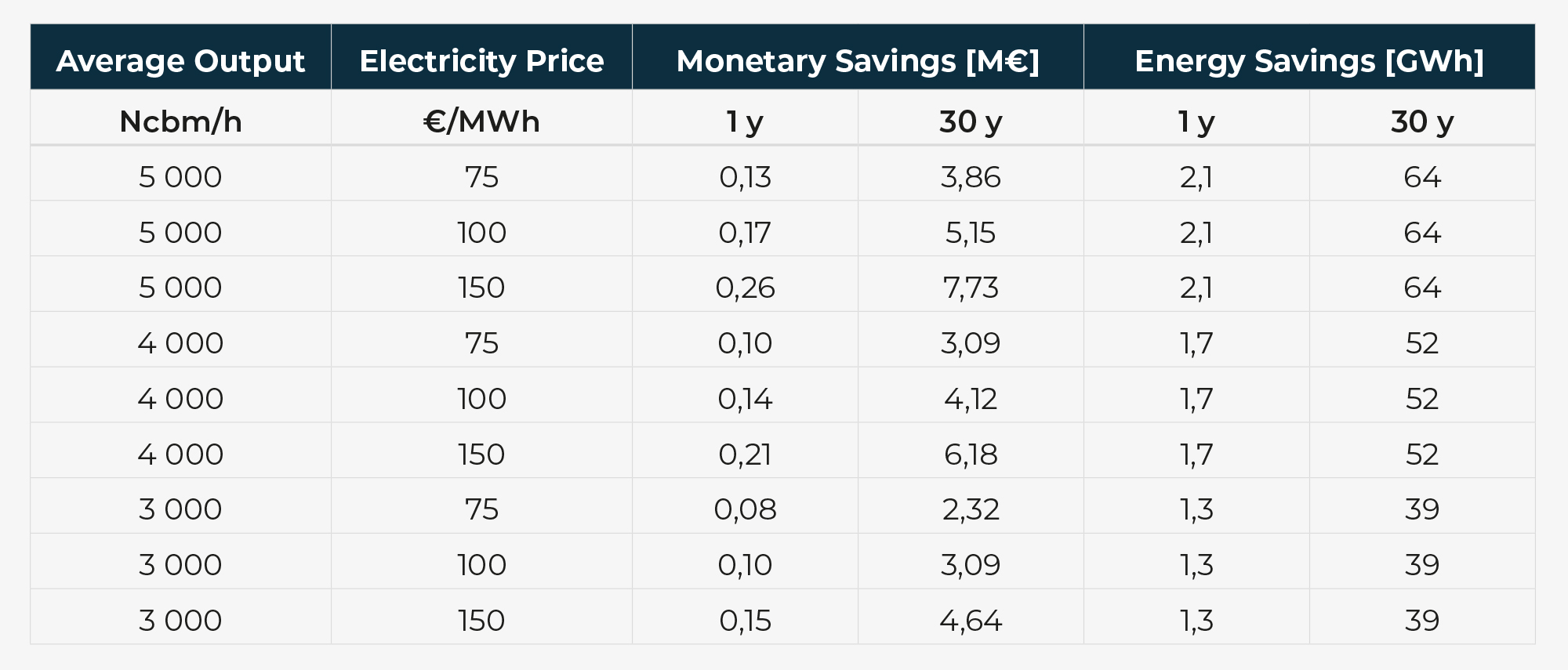

The Enairon Gravity Compressor presents a number of distinctive advantages over current compressed air solutions, including heightened flexibility, silent operations, extended lifetime, reduced service and maintenance needs, and liberated indoor production space. However, its primary benefit lies in exceptional energy efficiency, leading to substantial cost reductions. The extent of these savings is contingent on electricity prices and average air output. Notably, the calculator focuses solely on enhanced efficiency compared to existing industrial screw compressors, omitting considerations like reduced service costs and extended lifetime.

Enairon Green Air Service Package

The Enairon Gravity Compressor comes bundled with a comprehensive service package designed to provide our customers with a worry-free service solution, eliminating unexpected costs for repairs, service & maintenance. This all-inclusive package covers service & maintenance, support, software updates, technology license and API. Our service package ensures a dependable and environmentally friendly production of compressed air. The Enairon Green Air Service Package guarantees the most energy-efficient production of compressed air globally, reducing your carbon footprint and ensuring the cleanest possible operation in terms of energy consumption.

Included in the Enairon Green Air Service Package:

Service & Maintenance: Enairon continuously monitors the status and diagnosis of the compressor through VPN, providing annual service. Service and maintenance are encompassed within the service package; however, spare parts are not covered once the warranty period expires.

Support: Free support is available during office hours (07:00-16:00). Extended support hours with customer-specific SLA can be developed upon request.

Software Updates: Annual updates of the Enairon software platform.

Technology License: The Enairon Green Air Service Package grants user rights to use the Gravity Compressor.

API: The Enairon Gravity Compressor software is designed to communicate with external software platforms.

“The world’s most efficient compressor was successfully installed at Stora Enso AB in a jointly financed project between Stora Enso and Enairon. The purpose of the project was to save electrical energy and pave the way for a technology that could revolutionize the compressor industry.”

Mats Marcus

Area Manager Energy Efficiency at Stora Enso AB

Product data

- 400 kW motor power

- 78,43 W/Ncbm

- Efficiency >75%

- Consumes 37% less energy (range 30-50%)

- 5 100 Nm³/h in capacity at 20°C (85 Nm³/min)

- 7,5 bar in optimized output pressure

- MVSD (maximum variable speed drive)

Technical Specifications

– Enairon Gravity Compressor 400 MVSD-7

Enairon Gravity Compressor 400 MVSD-7 the next-generation compressor positioned to revolutionize air compression. Its exceptional energy efficiency, low maintenance, silent operation, long lifespan, and commitment to environmental standards make it a strong contender for businesses seeking peak efficiency, cost reduction, and a sustainable future.

Want to know more?

Whether you have an inquiry, suggestion or just want to say hello, don’t hesitate to get in touch. We are here to provide additional information and answer any questions you may have. Simply click the button below and enter your inquiry and we will get back to you as soon as possible.